Intelligent car PCBA manual assembly line

PCBA assembly line

Intelligent car PCBA manual assembly line

PCBA assembly line

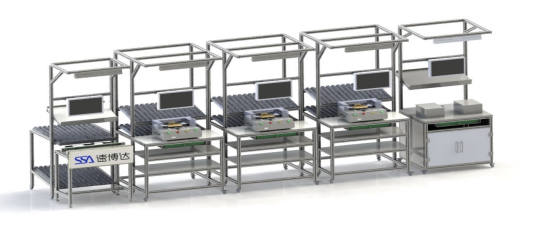

This automated production line is mainly used for the production and testing of intelligent vehicle control boxes; Composed of five assembly platforms arranged and spliced, combined with synchronous belt lines and manual transfer; In combination with specialized fixtures and positioning methods, the product is positioned through the positioning pins on the fixture. It requires both hands to simultaneously press the start button, and after testing, it can be manually removed, which can replace pure manual production in modern times.

The entire line has a small footprint, high space utilization, and beautiful equipment layout

The entire line adopts a one-stop operation, which is convenient for production management

Manual electronic signage, real-time monitoring, data uploading to MES

Strong product compatibility and equipment applicability

External dimensions

5.7m * 2m * 1.3m

Direct rate

≥ 98%

Conveying method

Belt line+manual labor

Noise

≤ 75db

Working air pressure

0.5-0.7Mpa

Number of stations

5

Capacity

Defined based on testing time

Final yield

≥ 99.8%

Data upload

Supports binding with MES

Working voltage

220V

Equipment power

/

Production manpower

5 people