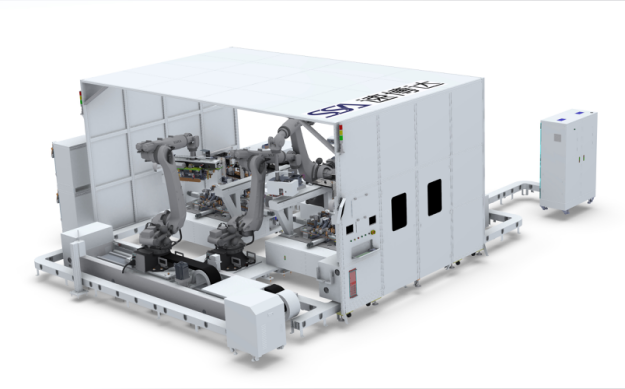

Full automatic side plate laser welding machine

PCBA assembly line

Full automatic side plate laser welding machine

PCBA assembly line

The equipment is mainly used for welding the side plate and end plate of power battery modules. The workflow of the equipment is as follows: the seven axis robot places the side plate, end plate, stacked battery cells, etc. into the welding slot, and the battery module automatically assembles, presses, positions, and welds. After the welding is completed, the seven axis robot grabs the welded module and puts it into the next workstation.

The welding parameters corresponding to the module barcode, such as welding time, power, speed, servo parameters, etc., are saved locally and uploaded to the MES system

Squeeze the end plate and battery cell with the reference edge, so that the total length of the module is controlled within ± 0.5mm, and the flatness between the end plate and the bottom of the battery cell is less than 0.3mm

After welding, the surface is smooth and free from burning, and there is a nitrogen gas pressure flow detection and adjustment device.

The laser adopts dual channel time-sharing light welding, namely YLS-6000-S2T

Size

9000x7000x2700mm

Welding speed

≤ 80 mm/s

Capacity

UPH ≥ 120

Laser power

6KW

Power supply voltage

AC380V ± 10%/50HZ

Crop growth rate

≥ 98.5%